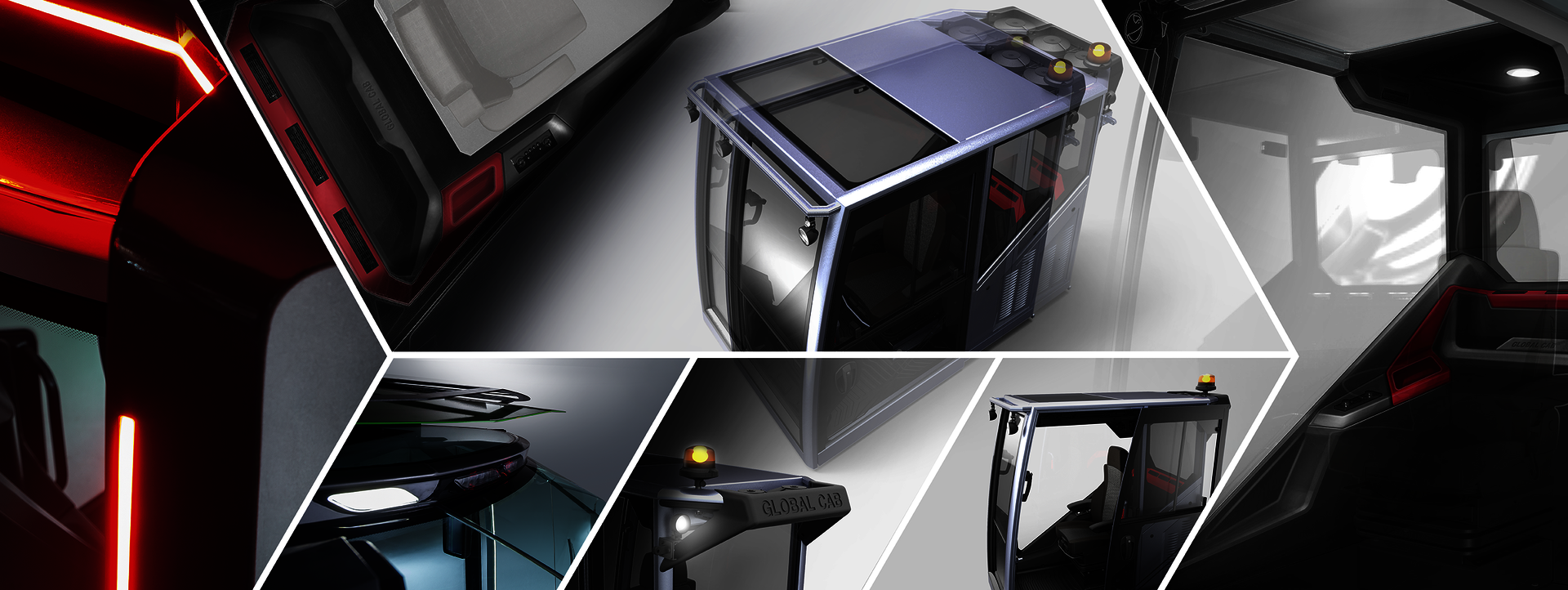

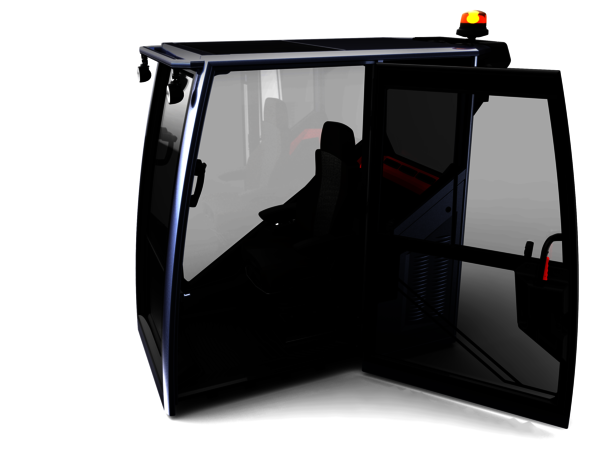

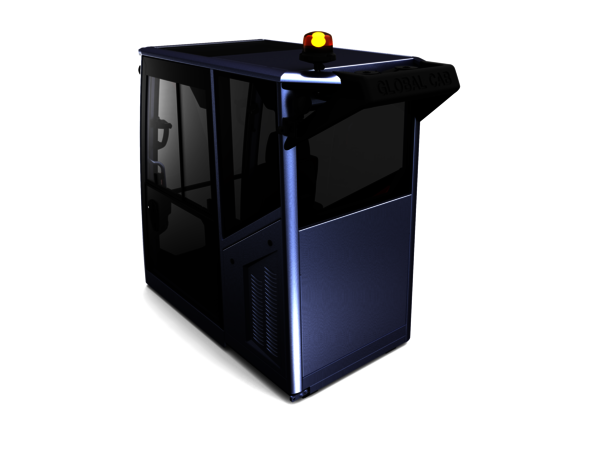

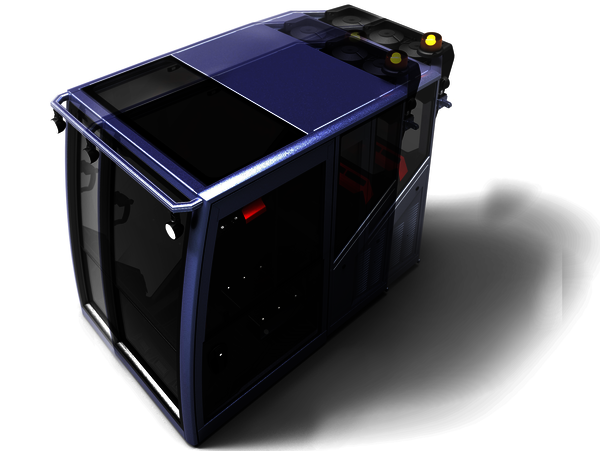

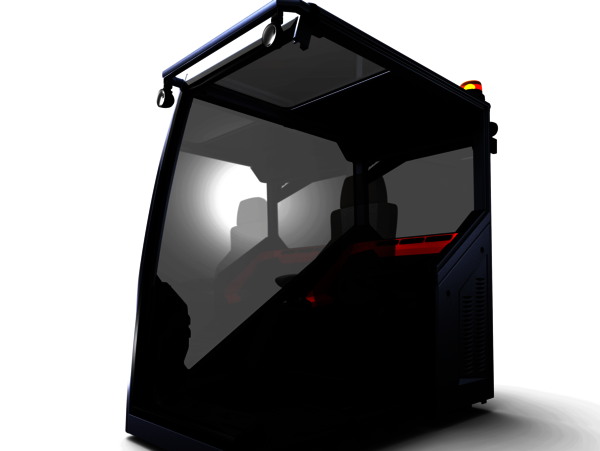

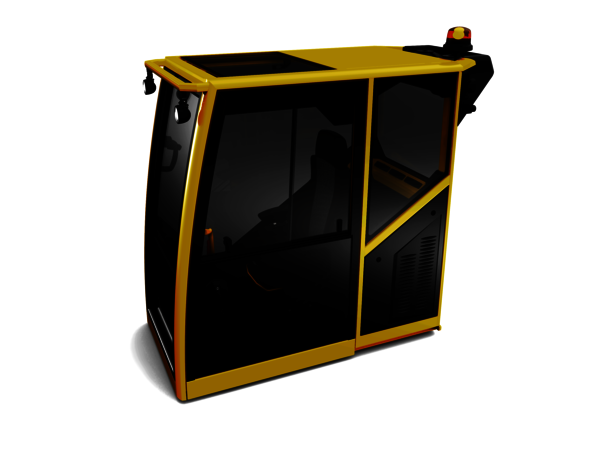

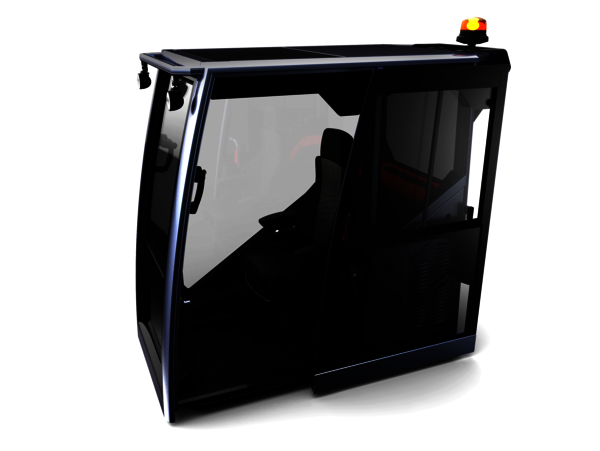

The Global CAB was designed especially for off-highway vehicle manufacturers who need a custom cab that meets their specifications, without long lead times and without high investment. Where weight reduction is important, as in cranes, the aluminium construction make it an obvious choice. Nevertheless the Global CAB is a safety cab (ROPS 20t) made of special aluminium profiles, that can be configured for a wide variety of machines and uses. For heavier machines the cab can be reinforced with an interior INNO-ROPS for loads up to 50t. Length and width can be varied by using different modular parts.

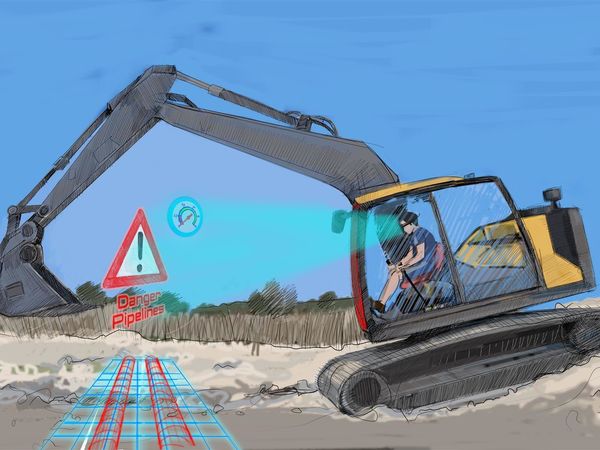

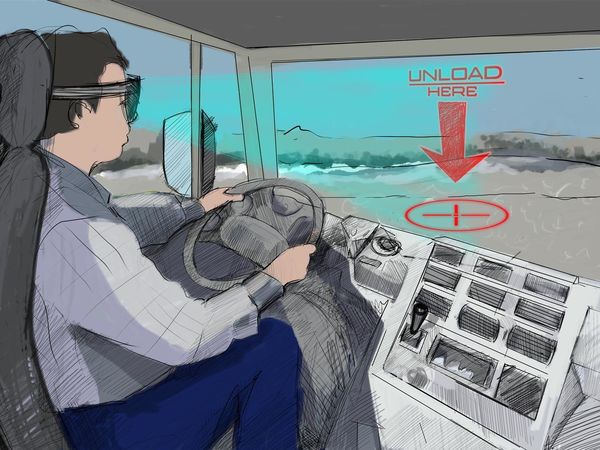

In cooperation with AR specialist Hololight, the Technical University of Munich, machine control specialist VEMCON and automation company MTS Maschinentechnik Schrode, Fritzmeier has been working on BIM applications. The use of BIM data bundled with sensor data from machines, supply line plans and hazard zones, shown over the real site as 3D models in mixed reality data glasses, brings many advantages. Everyone involved has access to all relevant construction site information at a glance, without having to consult multiple plans. For this development, Fritzmeier and its partners took first place in the bauma Innovation Award in the Science and Research category.

Further applications of Augmented Reality for Fritzmeier:

- Product development with AR configurator

- Ordering parts in daily operations

- Easy repair with AR instructions

- Using BIM data on-site and for training

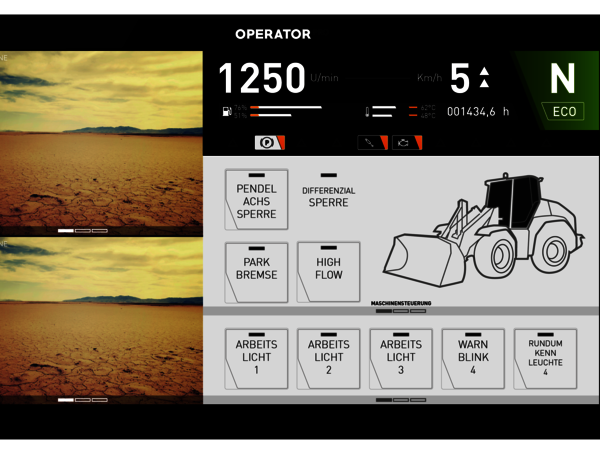

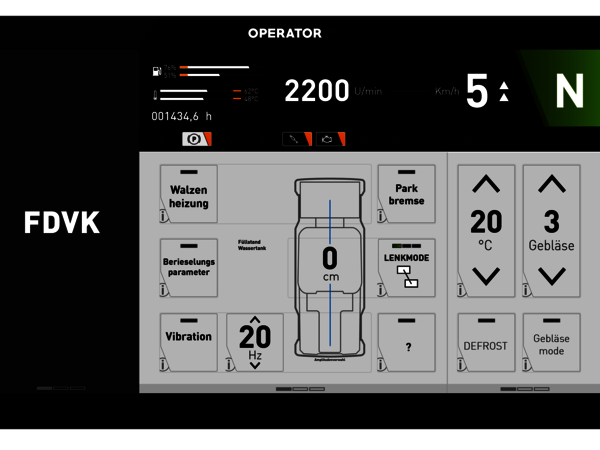

The complexity of machine control is increasing, as is the number of HMI variants. Operators often work with multiple machines, which makes orientation that much more difficult. To address this, the HMI Cluster and VDMA have joined forces to create a uniform standard when it comes to architecture, operating logic, structure and symbolic.

Active Noise Cancelling (ANC) solutions were offered only in headphones. Together with start-up recalm of Hamburg Fritzmeier CABS is showing a system that offers drivers considerably more comfort and freedom. Because integrating the system into the headrest of a driver seat, protects drivers from noise without blocking off the outside world.

As a family-owned company we generally have flat hierarchies, so everyone here has broad freedom in their area of responsibility. This is reflected in the Think BIG trainee project, in which young trainees from all areas of the company work together to plan and implement a project on their own.The result, a mini-construction site with robot arm and a truck designed and milled by the team.

Fritzmeier CABS makes over 50,000 cab systems each year for its customers. A cross-section of the company’s capabilities has been shows at bauma 2019. In addition, Fritzmeier CABS has shown various system assemblies made of synthetics and aluminium, with the focus on the functional integration and simple handling of these lightweight components.

On Wednesday Fritzmeier CABS presented the highlights to the trade press and interested visitors from all over the world.

If you have missed this highlight, we give you in the following video a brief review.