Plenty of companies talk about environmental protection, but Fritzmeier Systems puts it into practice.

The cornerstones of our environmental management system are:

- Compliance with environmental protection laws.

- Using energy efficiently and conserving resources.

- Avoiding, separating and recycling waste.

- Targeted risk prevention, for example by not using toxic or hazardous substances.

Our measures: Successes that encourage

- All materials we use in manufacturing are Cr6-free.

- Oily weld parts are cleaned in an environment-friendly parts washer before welding.

- Our coating system has switched to water-based paints for series production.

- We use only gas-powered or electric forklifts - no more diesel forklifts.

- Internal noise protection rules specify a maximum <78 dBA for machines.

- Through a thoroughgoing shift to reusable packaging and returnable load carriers we are continuously reducing our consumption of single-use packaging.

Thinking ahead - closing resource cycles

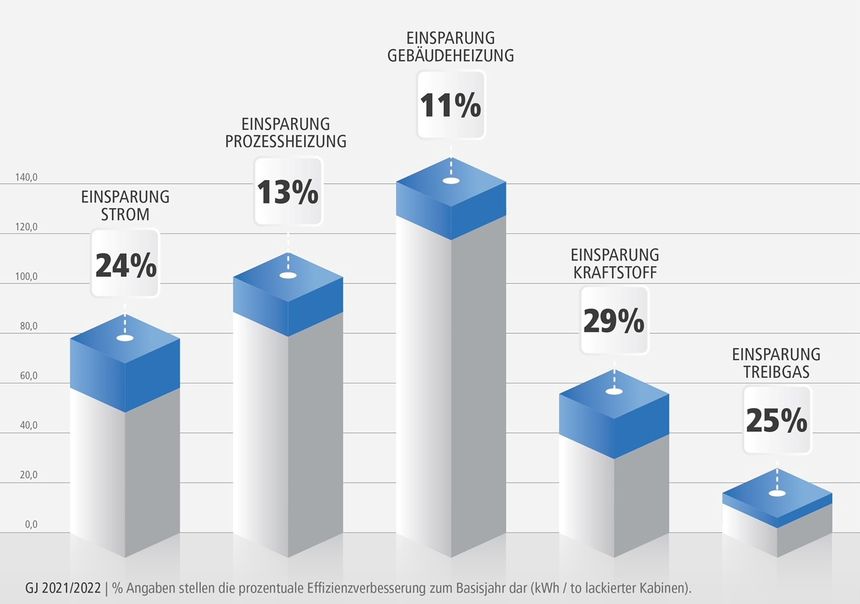

Since 2015 we have had DIN ISO 50001 energy management certification. This has helped us cut energy costs by systematically identifying energy consumption and reducing it by simple means.

- We use only recyclable materials.

- The requirements of DIN ISO 14001 will be implemented and binding for our entire supply chain.

- In regular energy audits we look at additional ways to recover energy from production processes, avoid waste, and so reduce costs.