17

A reliable, efficient machine park is necessary for production at high quality and with consistent precision, so Fritzmeier Technology invests in the latest equipment year by year. This ensures that the company with its approximately 110,000 m² of production space retains its innovation lead in manufacturing, and can offer customers enormous performance with high cost efficiency for every sub-step and every process.

Each year we use over 10,000 tonnes of steel in various thicknesses and table sizes.

Machines used to work sheet metal:

- 2D and 3D lasers

- Hydraulic presses

- Hydraulic press brakes

- Bending robots

- Milling and drilling machines

- Grinding robots

- Stamping and nibbling machines

Whether A-pillars, B-pillars or reinforced roof structures on a cab, the right bent section gives the metal components of a chassis the necessary stability and rigidity.

With the latest tube bending and lasering machines, each year Fritzmeier works 2500 tonnes of section for safety cabs. Our project teams make full use of all optimization potential, from prototyping to tool-making to steel construction and final assembly.

Machines used to work section:

- Tube bending machines

- Tube lasering machines

Mobile work machines are designed and built for heavy-duty use. Our joining techniques are specially designed to meet these demands. We weld manually as well as with robots. We have over 26 welding robots in our production facilities that join all parts with precision, around the clock. Other joining techniques we use are sheet metal bonding, with two robots.

Machines used to join metal:

- Welding robot

Bonding robots

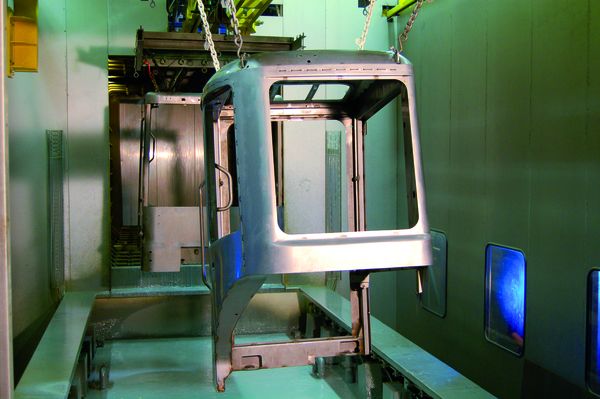

Steel working technologies

The Fritzmeier Cab Group has painting lines at four locations, making it Europe’s leading cab maker as regards painting capacity. We operate special systems for alkaline cleaning followed by zinc phosphating on steel, ED and CED dip priming, and wet/powder coating for the final topcoat. We can also do extensive quality inspections in-house, like crosscut, gloss level, coat thickness, colour measurement, mandrel bend and salt spray testing. We use water-soluble, environment-friendly coatings. If desired by the customer, we can paint in many special colours and in lot sizes down to 1.

Conveyor System:

Continous running installation AED

Power and free topcoat

Pretreatment:

5 zones

Alcalic cleaning

Zinkphosphating (Henkel)

Primer:

AED (Axalta)

Topcoat:

1-K-waterbased topcoat

Conveyor System:

Running / Power and Free

Pretreatment:

9 zones

Alcalic cleaning

Zinkphosphating (Henkel)

Primer:

CED (PPG)

Topcoat:

1-K-waterbased topcoat

Conveyor System:

Running / Power and Free

Pretreatment:

5 zones

Alcalic cleaning

Etching (Henkel)

Primer:

-

Topcoat:

powdercoating

Conveyor System:

Takt / Power and Free

Pretreatment:

9 zones

Alcalic cleaning

Zinkphosphating (Henkel)

Primer:

CED (PPG)

Topcoat:

2-K-solvent based topcoat